Error

Site designed and built by David Power ✌️

At Uber, we needed a safer and more efficient way to test autonomous vehicle interactions with moving objects - like pedestrians, bicyclists and animals - in any relevant scenario. Test track collisions between cars and objects are common - many times by design in order to collect accurate data. With that in mind, the solution had to be relatively inexpensive, durable, and easily repairable.

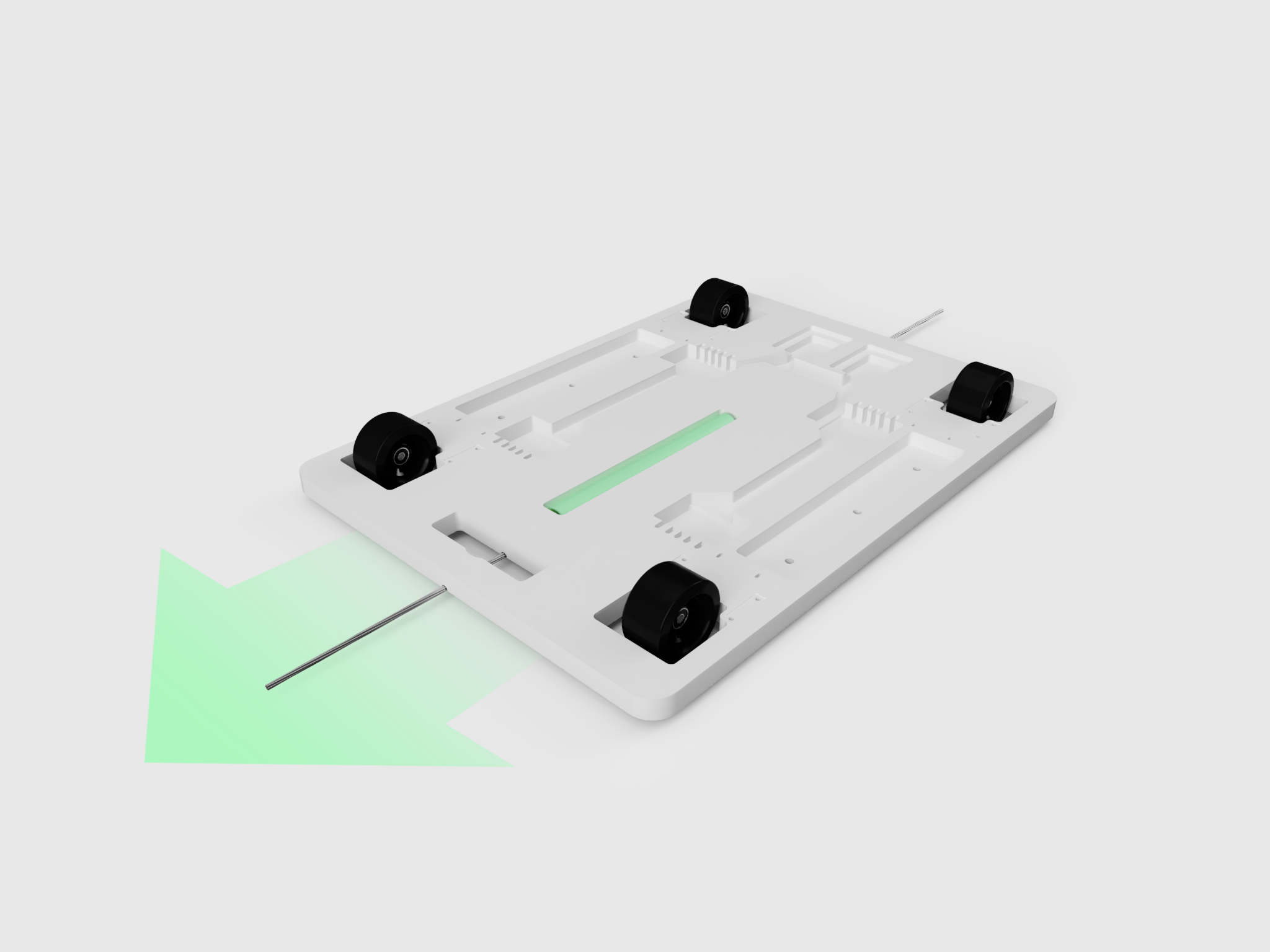

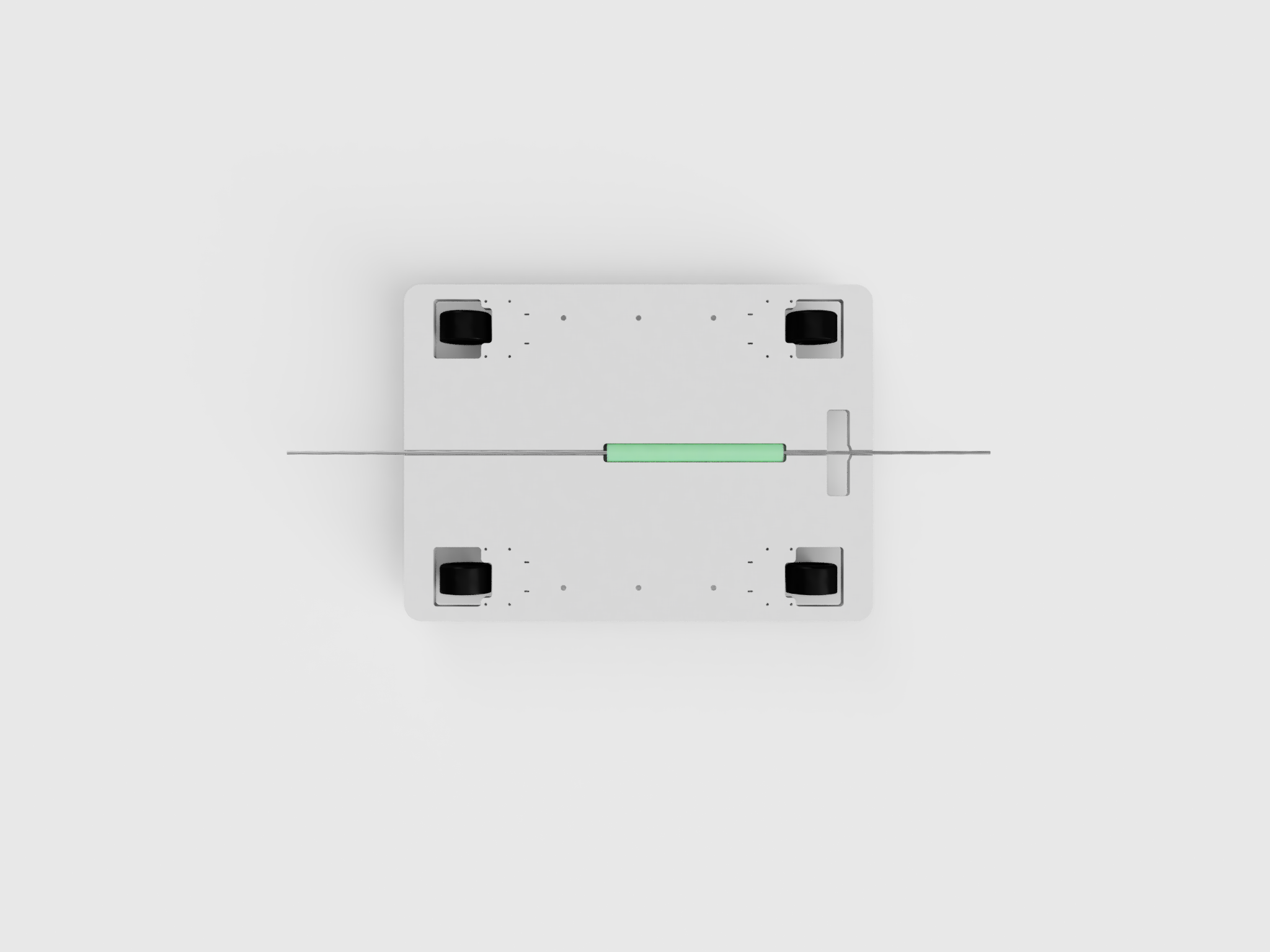

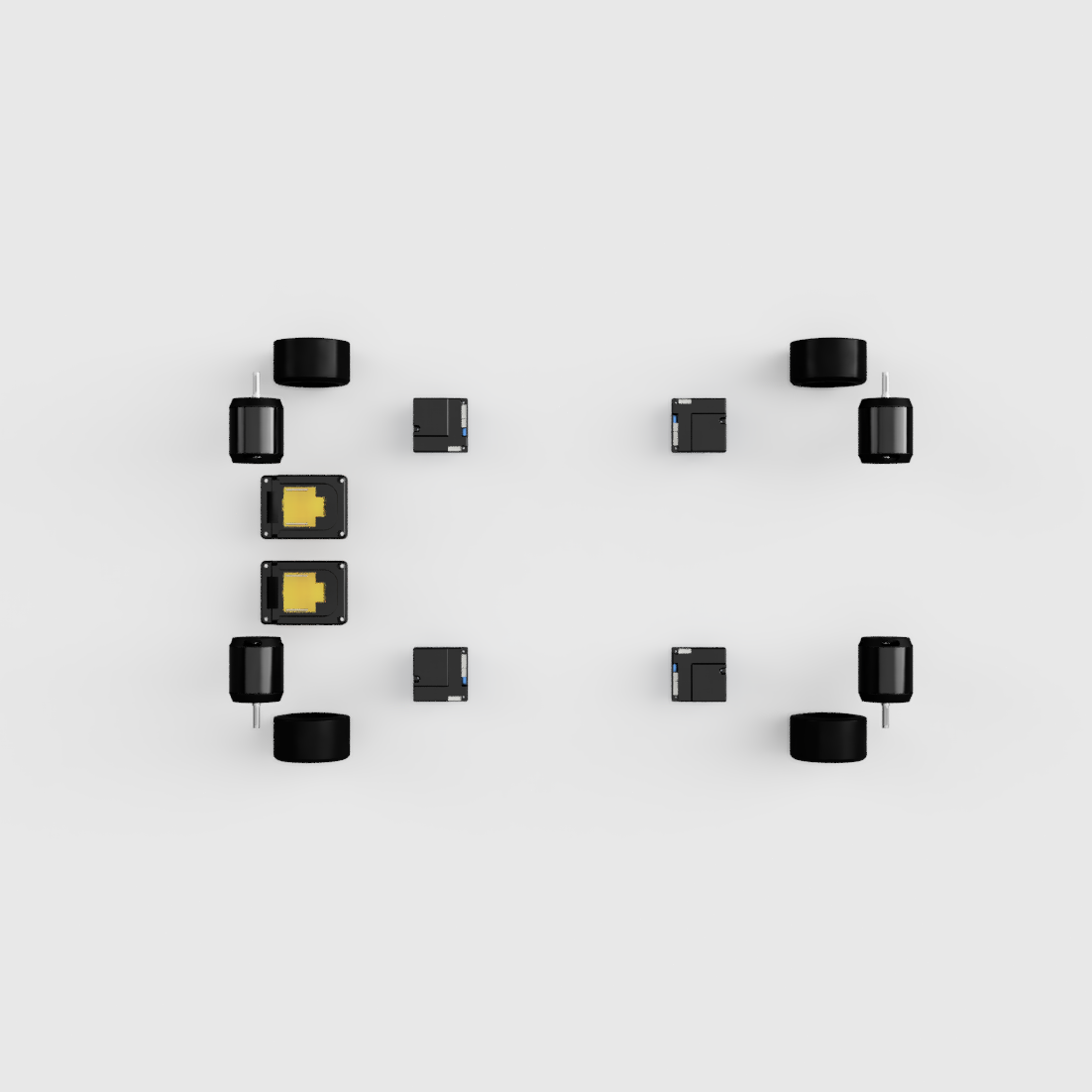

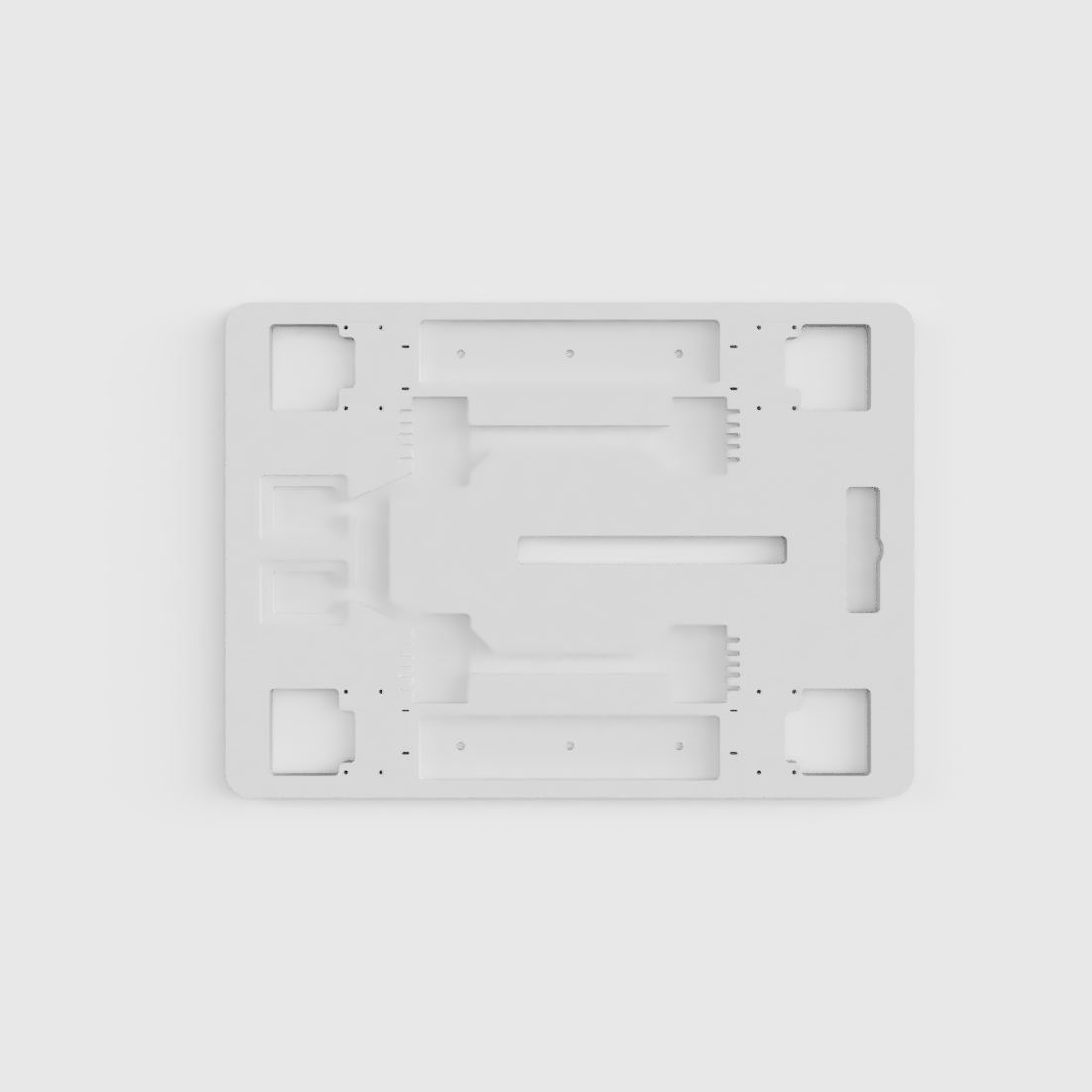

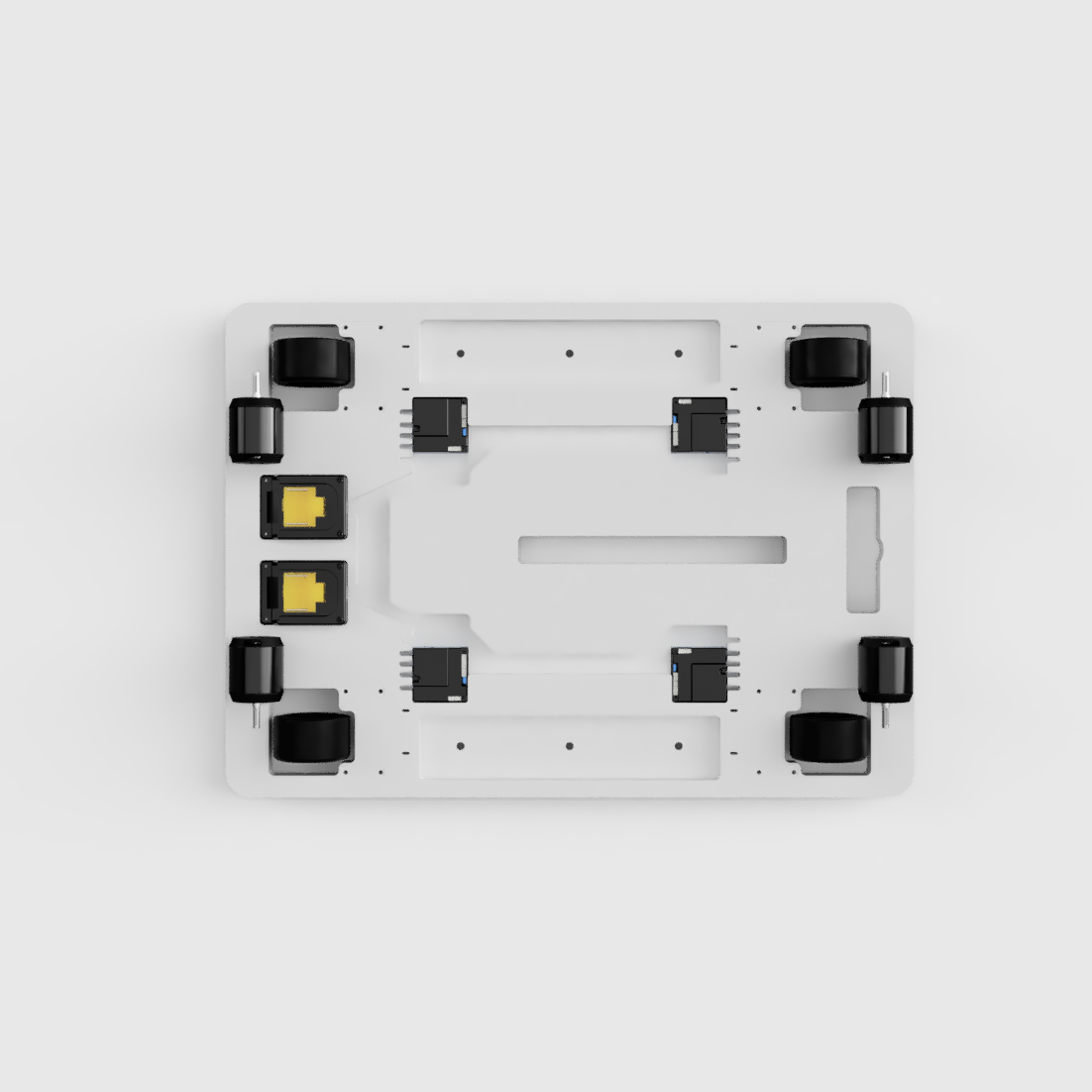

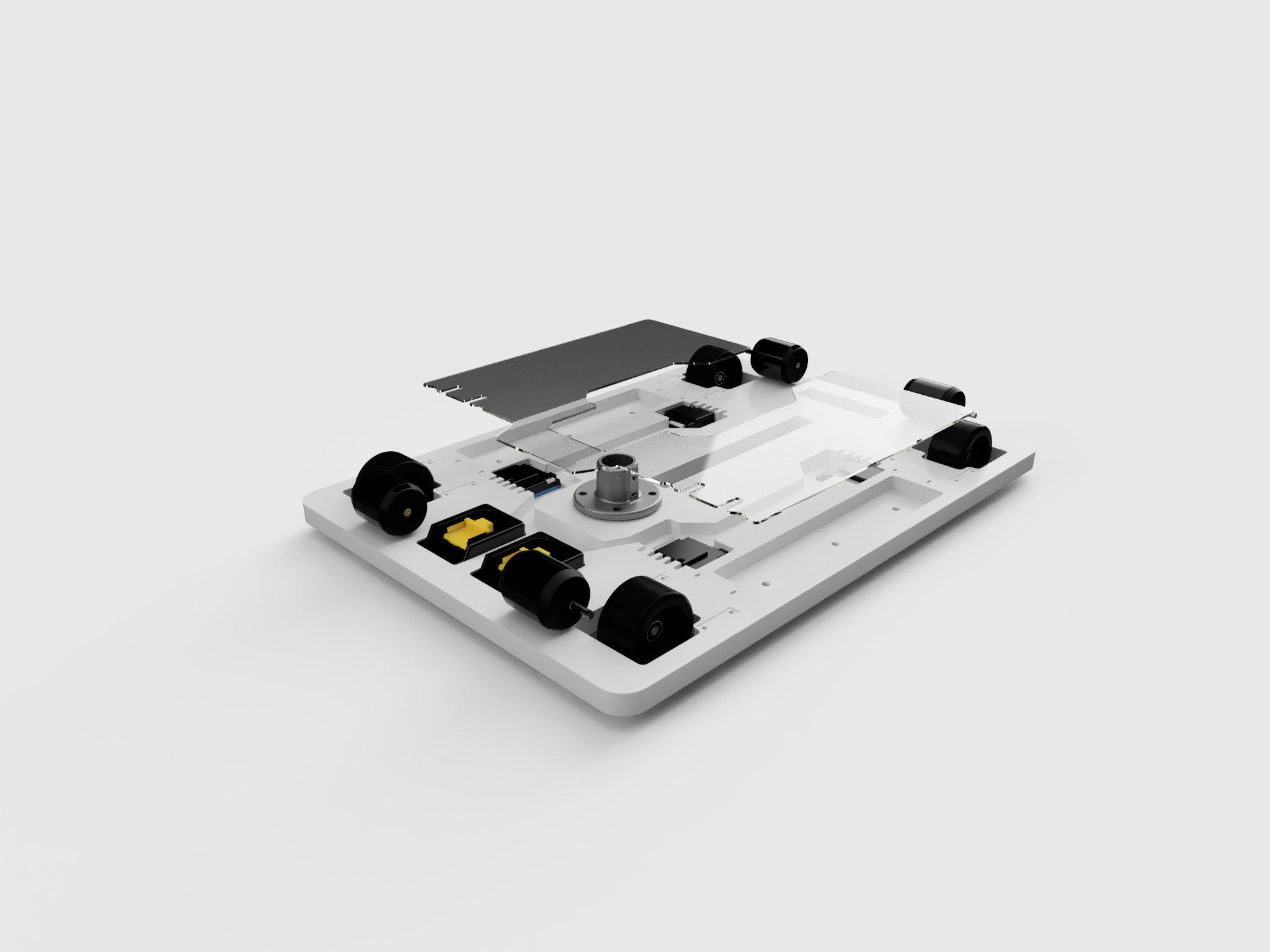

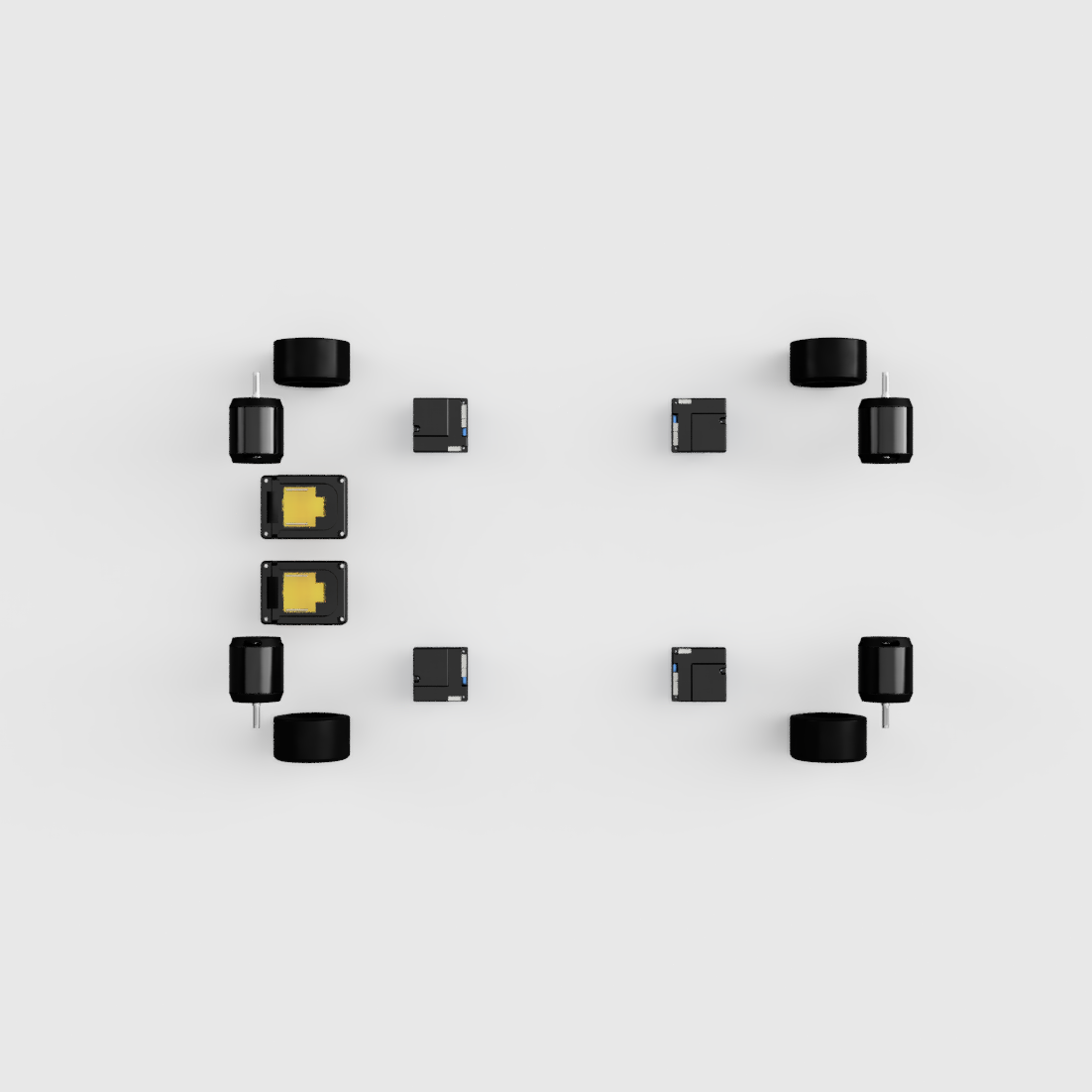

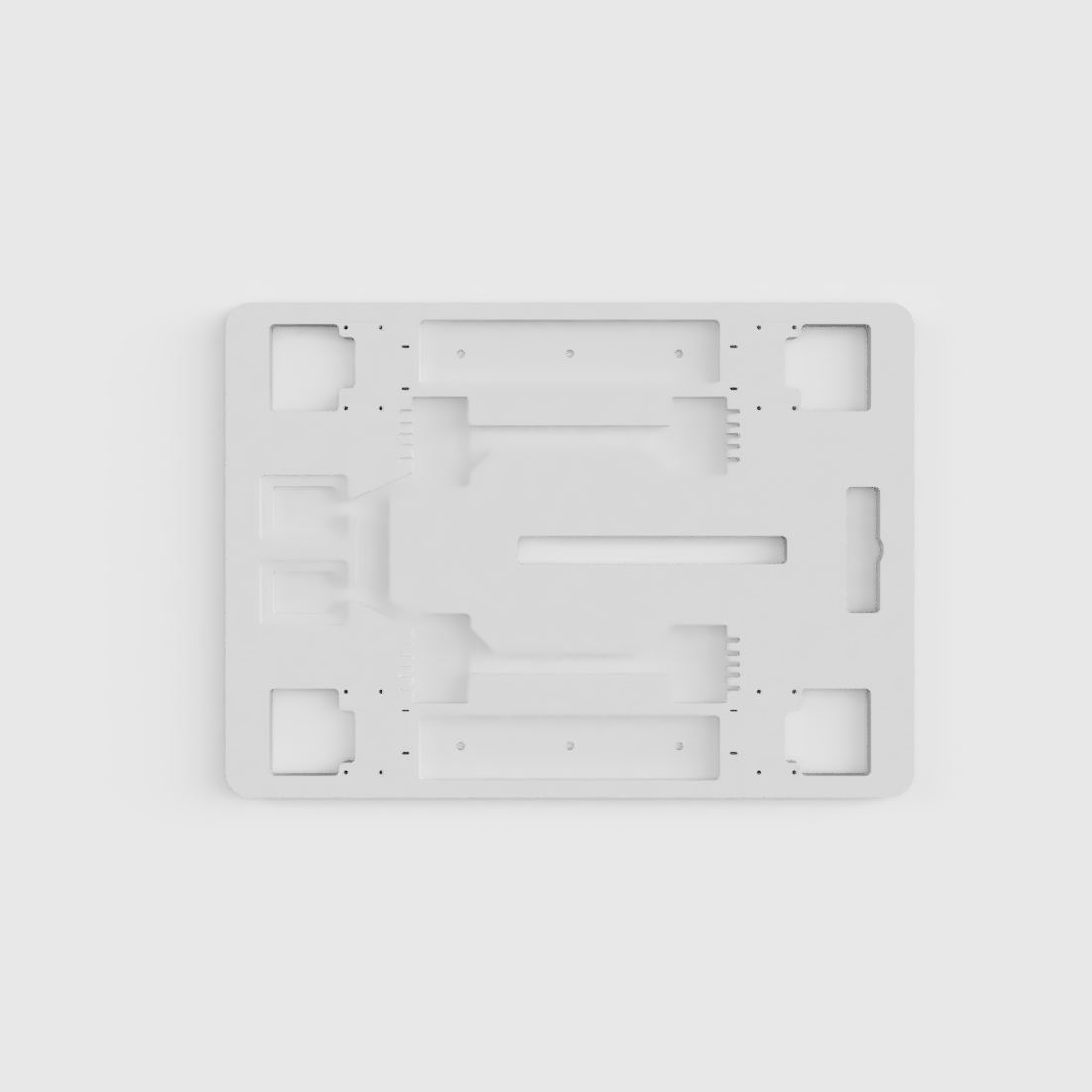

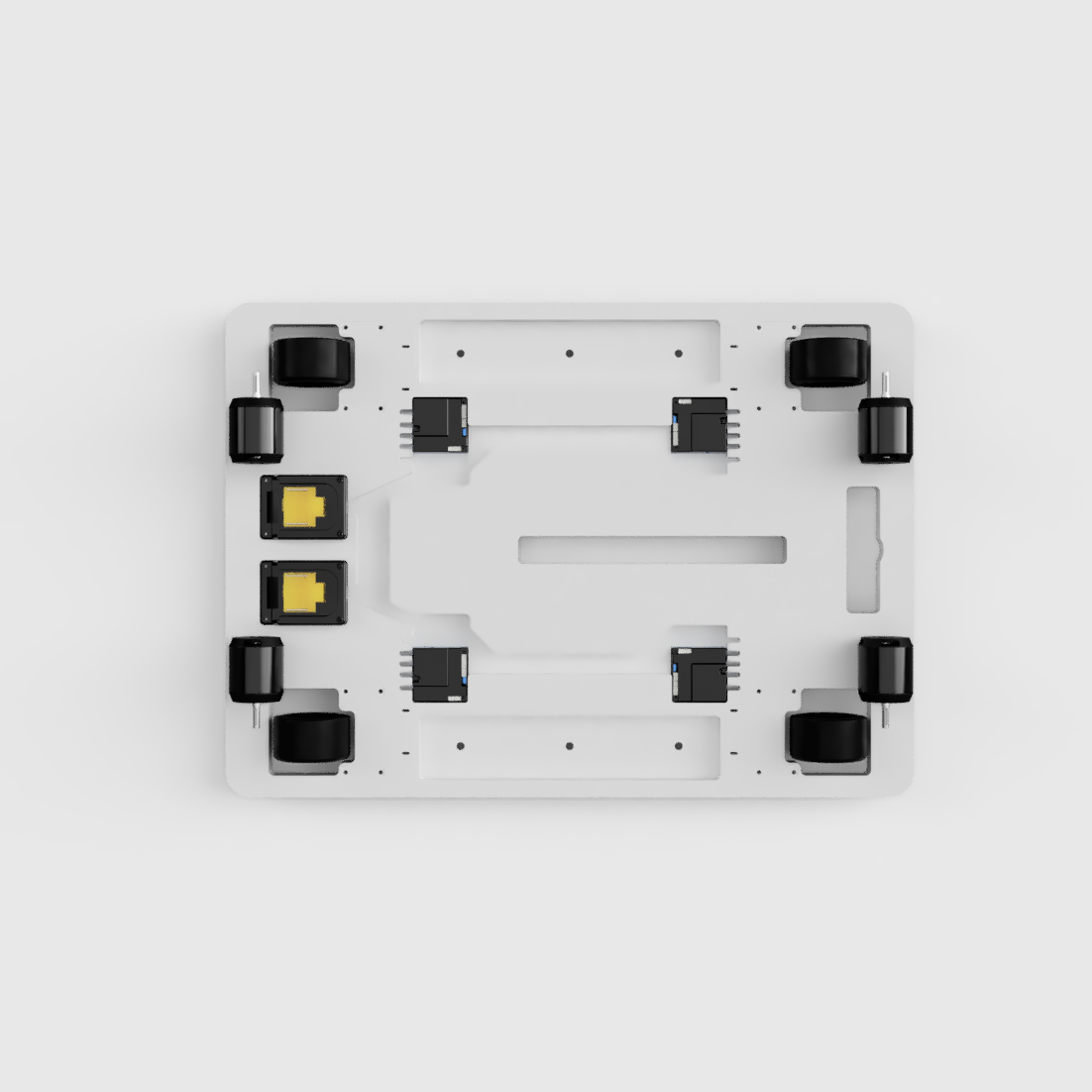

Our solution was a radio-controlled mobile platform with a universal mounting point where any test object could be quickly attatched and sent out for a test. Its flat profile allows it to survive many types of impacts, while all components (most available off the shelf) are designed to be easily repaired or replaced. By building out a small fleet of bases, we could always be prepared for a full day of testing while minimizing preperation time. The unit is powered by two lithium ion Makita power tool batteries which could be swapped out and quickly recharged.

Each wheel is driven by a brushless motor controlled by an electronic speed controller (ESC). An RC controller communicates with the ESCs via a reciever. Dual joysticks give you full control to drive the base up to ~20mph, stop on a dime, or turn. The base can manuever in a variety of ways from big sweeping turns, to tight 0º turns thanks to its individually controlled wheels. Space for the electronics and wiring is milled into the high density plastic base and covered with a shield, so it can survive most collisions. The wheels are mounted to spring loaded brackets that act as a suspension, allowing it to bottom out without failing when being run over by a vehicle. If any part does get damaged, it can be replaced on the spot in minutes.

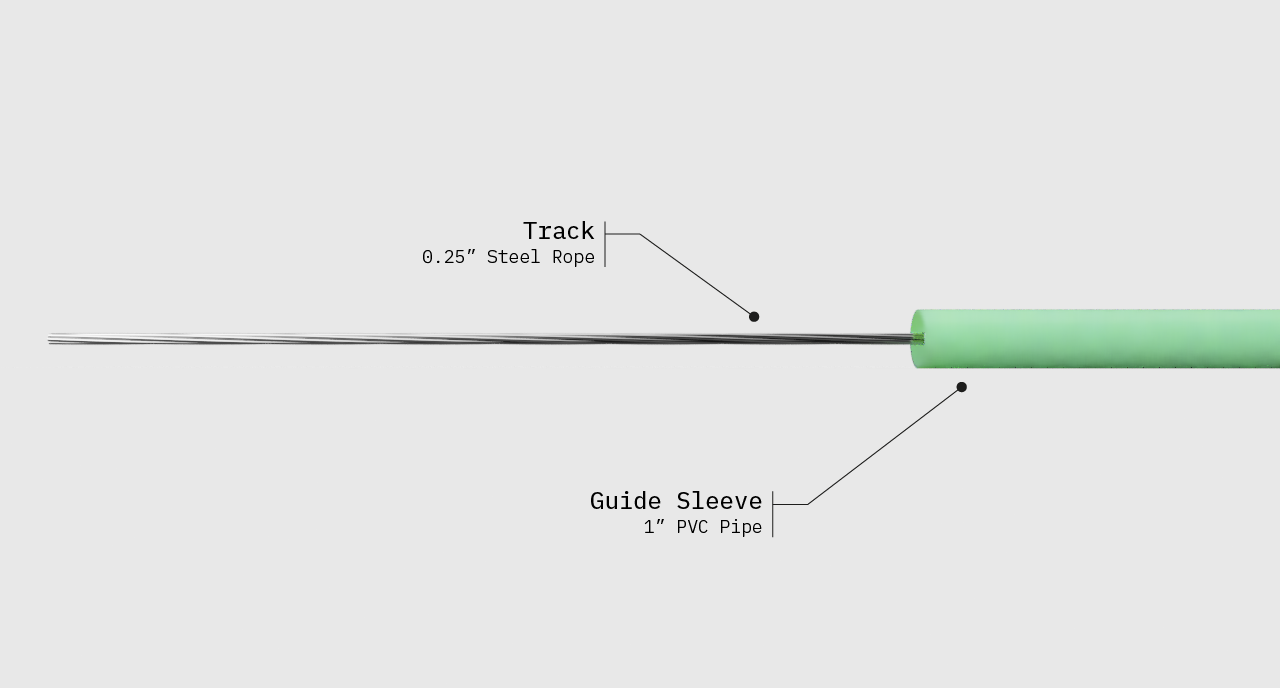

For situations that favor straight lines and repeatability over complex turns and manuevers, the base can be tethered to a steel wire rope which helps make test runs more repeatable and controlled. The steel rope is anchored at the start and stop points while a short piece of PVC pipe sits in the middle of the base, guiding it along the steel rope. This added control frees up the operator to focus on speed, timing, and other requirements of the test scenario.

Anchors are installed directly into the asphalt track in minutes with an SDS hammer drill. For observer safety, the steel rope is attatched to the anchors with low-strength caribiners acting as failsafes to prevent the anchors or rope whipping across the track in the event of extreme entqnglement with a vehicle.